The Latest Inspection Systems

Print quality inspection expert EyeC is presenting its newest inspection systems from May 4th to 10th at Interpack in Düsseldorf. The company will show visitors the newest in-line inspection technology for the 100% examination of folding cartons and luxury packaging. EyeC will show the EyeC ProofRunner Carton Pre-Feeder in action on the folder-gluer from Kohmann. With this system, carton manufacturers can use the latest technologies directly in their existing processes without replacing their existing folder-gluers. EyeC says that the module can be easily connected to any folder-gluer. The inspection system even checks the print quality of text, graphics, colours, and foil stamping, as well as 1-D and 2-D codes on the entire carton surface. Defective boxes are ejected via the ejection device of the folder-gluer before the production is delivered to the customer. The EyeC ProofRunner Carton HiLight system inspects the special combination of hot foil and blind embossing for high value materials such as complex luxury folding cartons. EyeC is demonstrating the use of this inspection system on the PrintChecker sorting unit from Kohmann while at Interpack. The in-line system is also offered as a pre-feeder module or a retrofit module. In addition, EyeC is presenting the Proofiler 1200 DT, a new flatbed scanner capable of scanning documents in size up to 1,270mm × 915mm and checking them against an approved PDF file in one inspection run. The EyeC Proofiler 1200 DT also offers other options such as checking colours, 1-D and 2-D codes, or braille.

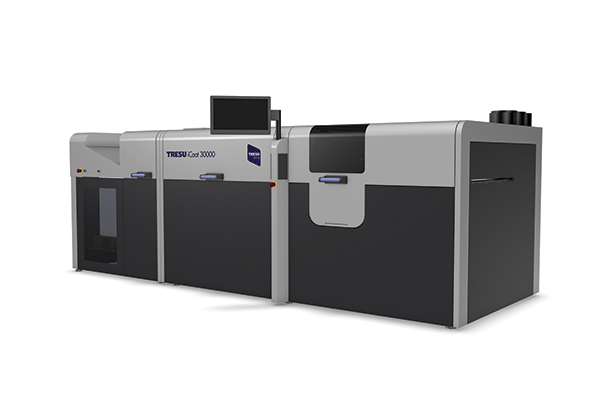

Carton Coating with HP Indigo

Tresu exhibited a complete workflow for integrated inline coating and metallic finishes on HP Indigo presses, for folding cartons and synthetic materials, at Dscoop Phoenix in Arizona in the US from March 1st to 4th. The Dscoop convention brings over 2,000 users of HP Indigo digital printing technology together with partners and vendors to share ideas and learn about new technologies, services and opportunities. Live demonstrations of the Tresu iCoat flexo coater, working with the HP Indigo 30000 digital press, showed how added-value post-print varnishes can be applied at speeds of up to 4,600 sheets/hour. The same production line featured a new compact flexo printing unit, integrated to a peristaltic pump, named Tresu Flexo Kit, for rapid application of high-gloss metallic, aerodyne, and other special effect coating finishes. Fast changeovers of sleeves and automatic chamber cleaning on both units minimize setup times to within five minutes. The company also featured its own iVarnish line of UV and water-based coating material that is specially formulated for the digital printing line. At Dscoop, Tresu presented new varnishes with improved adhesion properties so that plastic as well as board substrates may be run. One potential application is the retail loyalty card.

New Clear-on-Clear Label Adhesive

Clear-on-clear labels can be problematic if required to withstand wet conditions. The framing effect occurs when moisture causes an unsightly white haze to creep across the applied label from its edges. This problem is eliminated by the highly transparent label adhesive 62F, which is available from Herma. It was developed specifically for clear-on-clear applications in which moisture is a factor, as in the drinks industry. Even when tested by immersing in water for 96 hours, Herma claims that it failed to trigger any clouding. The adhesive is further characterised by high initial tack and very good resistance to oils and aqueous media. The permanent UVA adhesive is designed specifically for challenging and critical applications in the cosmetic, food and pharmaceutical industries in particular. Alongside its other benefits, the 62F grade is not subject to secondary cross-linking (unwanted hardening) in connection with multi-colour printing and prolonged UV curing. In view of its unconditional approval by the German test institute ISEGA, it is also suitable for direct contact with dry, moist and fatty foodstuffs. Herma says that the new adhesive 62F is most effective in combination with the label film Herma PP 50 transparent (grade 885) and that this film delivers good print quality with all the conventional printing techniques.

Digital Thermal Transfer Printing

The advantages of digital thermal transfers using premium foil and automated application systems were presented by Diamond Photofoil at the Xeikon Café Packaging Innovations 2017 (March 28th to 31st). A range of applications for digital transfer printing were shown on a wide variety of products, including pens, packaging tubes, ice buckets, and point-of-sale displays. Diamond Photofoil’s high-resolution digital transfers applied in automated printing lines for tube products such as pen barrels and cosmetic packaging were demonstrated live. Developed by Diamond, Photofoil digital printed transfers provide full colour photo realistic printing for plastics with no origination cost and short lead times direct from digital artwork. Companies that took part in the Xeikon Café Packaging Innovations 2017 event included AB Graphic International Ltd, Agfa Graphics, Avery Dennison, Esko, Flint Group – Narrow Web, Flint Group – Sheetfed, Flint Group Flexographic products, Highcon Systems Ltd, Hybrid Software NV, Iggesund Paperboard, Meech International, Metsä Board, Scodix, Stora Enso, Tresu Group, UPM Raflatac, Xeikon and Zund. Visitors saw innovative technology that demonstrated how digital production can be beneficial in a number of market segments:

Automotive:

Digital printing with integrated MIS systems and finishing optimise the automotive supply chain and strengthen the dealer/customer relationship by personalising packaging. (Presented application: folding carton packaging).

Beverage & Wine and Spirits:

Standing out is vital in this market. A perfect example is the wine and spirit market, with its use of numerous embellishments (foiling, spot varnishing, embossing, etc) and challenging materials to print the natural, structured facestock paper. (Presented applications: wet-glue labelling, wraparound labels, clear on clear, self-adhesive labels and hot beverage paper cups, and specifically for the wine and spirit market, folding carton and corrugated carton).

Food:

At the Xeikon Café visitors discovered a digital production solution that has no mineral oils, no UV components and is food safe. (Presented applications: in-mould labelling, heat transfer labelling (therimage), self-adhesive labelling, folding carton, flexible packaging and pouches).

Health & Beauty:

Special materials like transparent facestock which provide a no-label look on plastic containers and metalised folding carton boards are commonly used in this market and require a printing solution capable of delivering the highest quality. (Presented applications: self-adhesive labels, promotional heat transfer label, folding carton).

Media:

The revival of vinyl records were one of the first drivers of digital printing in producing sleeves. At the Xeikon Café a 360° concept regarding promotional items that touch on the music industry was shown. (Presented application: folding carton).

Pharma:

The Xeikon Café presented a full concept for this market, including folding carton, leaflets, labels and counter displays, with features such as track and trace and anti-counterfeit capability. (Presented applications: self-adhesive labels, leaflets and folding carton).

Promotional:

Digital heat transfer decoration is of interest to self-adhesive label printers looking to diversify, or injection moulders looking to bring product decoration in-house. (Presented application: heat transfer labelling).